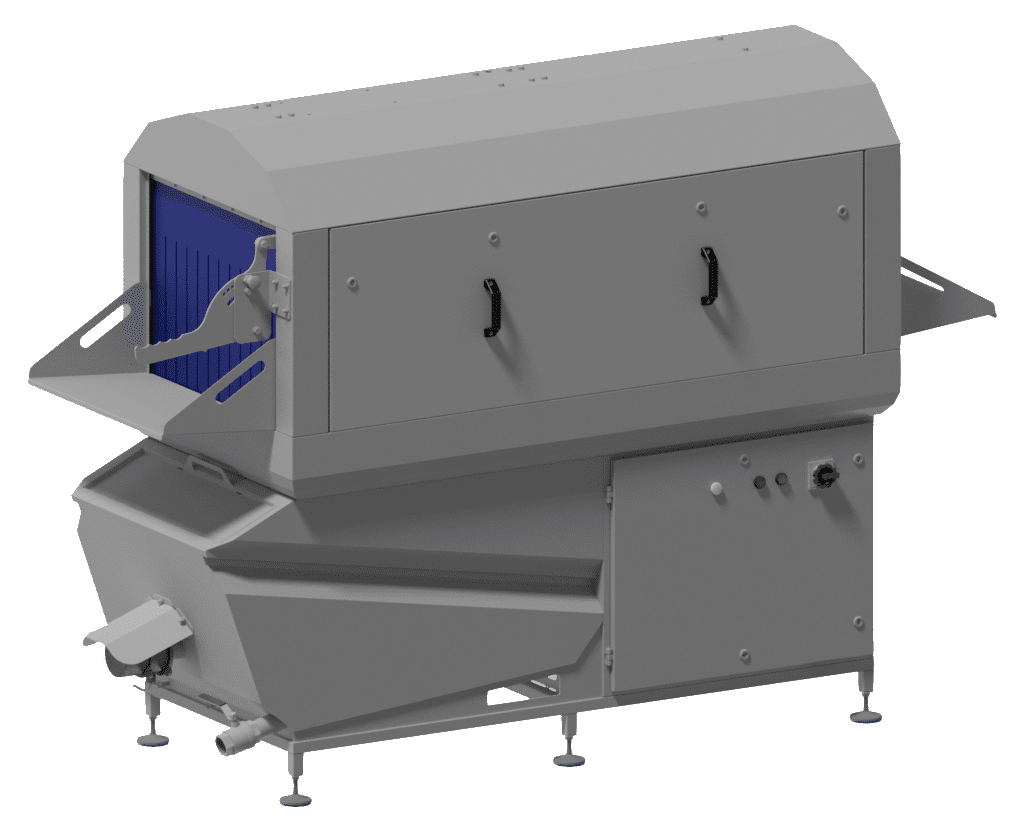

The LWA line washing system -

Efficient cleaning for crates

Capacity: 100–2,500 crates per hour.

More enjoyment with clean crates!

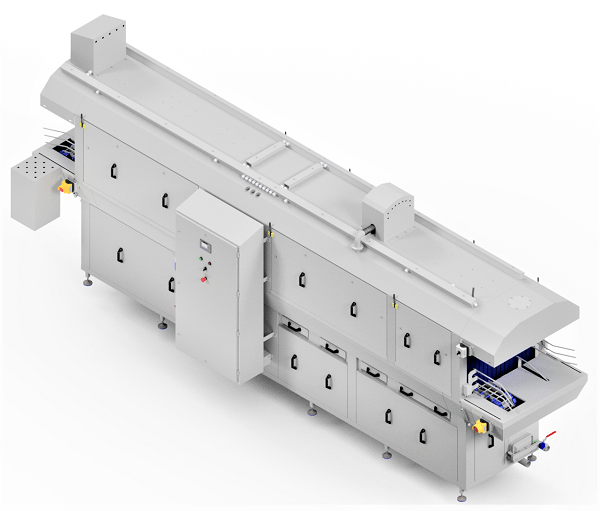

The crate washing system is also known as a crate washing machine. It is made of high-quality stainless steel and has a hygienic design thanks to HACCP standardization.

The washing systems are adapted to the crates to be cleaned. Thanks to an integrated water filter, the crate washing systems are extremely resource-efficient when cleaning crates and boxes.

A drying function can be integrated as an option. The size of the items to be cleaned can vary, as the machine is adapted to the items to be cleaned by the respective company.

Top washing results

Washing zone

Crates are thoroughly washed on all sides and inside in a circulating washing zone. The built-in filter system continuously cleans the washing water in the washing zone. This helps to reduce germs and bacteria. The built-in tank heating system of the washing systems maintains the temperature of the washing water.

Top disinfection results

Rinsing zone

In the rinsing zone of the crate washing system, the crates are rinsed with hot, clean fresh water and thermally disinfected (optionally, the crates are cleaned in the washing systems with the addition of cleaning agents or disinfectants). This water is then optimally fed into the main washing zone of the washing system and reused. This unique process achieves maximum washing results for containers and crates with minimal water, energy, and chemical consumption.

Top drying results

Drying zone

On request, a drying module can be integrated into the crate washing machine. Drying is fast, efficient, and of the highest quality. The size of the crate washing machine is adapted to your company. The washing systems from the manufacturer Heim – EDT thus generate minimal operating costs with the best cleaning results.

For crates with gripping edges or less than 300 pieces per hour, we recommend our crate washing system. You can find more information here:

Information Hygiene lock

Containers and washables

The following items can be cleaned in our washing machines:

- Basket(s)

- E1

- E2

- E3

- Box(es)

- S-Performance containers and boxes

Are you looking for a line washing machine for containers of a different length, shape, or size?

No problem, contact us and we will find a solution together. We customize all machines individually to the items you want to clean in order to achieve the perfect results for you and ensure optimal hygiene.

Options and accessories

All our crate washing machines can be equipped with the following options and accessories:

- Drying module

- Spin dryer for drying

- Water filter

- One-man operation

- Conveyor belts

- Dosing pump

- Steam extraction

- and much more

If your desired product specification is not listed, please contact us directly and we will design the machine according to your requirements. For detailed prices and information about a system, please contact us directly.

Technical data

The technical data for a crate washing system (HLCV.1) for cleaning 200 crates per hour is listed below:

- Machine dimensions: 2,300 x 800 x 1,625 mm

- Material: Stainless steel 1.4301 T=2.0 mm

- Conveyor belt speed: 1.75 m/min

- Pump: DWO300

- Washing pump power: 2.2 kW

- Washing nozzle flow rate: 500 l/min

- Approximate water consumption: 0.5–0.6 l/crate

- Washing temperature: 30–60°C, adjustable

- Nozzles: Clip-eyelet (rotatable flat jet nozzles)

- Filter system: Plug-in sieve made of stainless steel 1.4301 filter mesh

The dimensions and components of the crate washing machines are adapted to the requirements of your company.

Quality made in Germany

Industrial crate washing systems directly from the manufacturer

Crate washing systems are the optimal solution for washing product-specific crates. The crate washing systems feature a hygienic design, unparalleled quality, and innovative technologies for fast and effective cleaning. Depending on the type and system, the washing systems are also called crate washing machines or crate washers. A crate washing system can be divided into a washing zone and a rinsing zone.

Cleaning

Products to be cleaned are washed in a circulating, water-filled tunnel. The built-in filter system continuously cleans them in the washing area. This helps to reduce resource consumption and costs. The built-in tank heating system of the washing systems maintains the washing water temperature, thereby saving additional important resources.

Rinsing and disinfection

In the tunnel of the rinsing zone of the crate washing system, the containers are rinsed with hot, clean fresh water and thermally disinfected. This water is then optimally fed into the main washing zone of the washing system and is available for reuse. Depending on the model, the manufacturer can optionally integrate a drying solution for the containers into the interior of each tunnel.

Enquire now:

Contact

Address

in der Spöck 12, 77656 Offenburg

Contact persons

- Jörg Walter

- Geschäftsleitung

- j.walter@bw-fpe.com

- +49 (0)781 / 127 864 13

- Kilian Rebmann

- Konstrukteur

- k.rebmann@bw-fpe.com

- Isabella Walter

- Buchhaltung

- info@bw-fpe.com

- +49 (0)781 / 127 864 13