Hygiene sluice for effective operational hygiene

Capacity: 10–200 people per hour

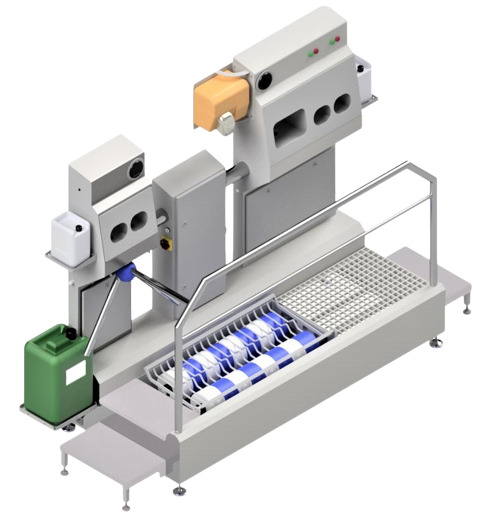

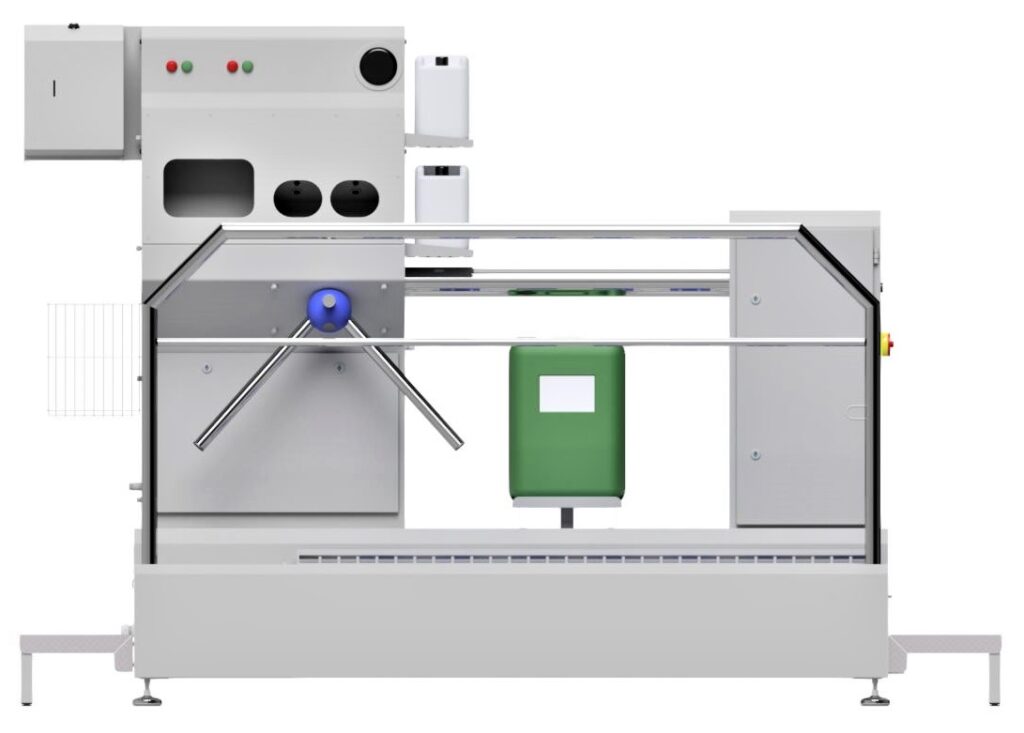

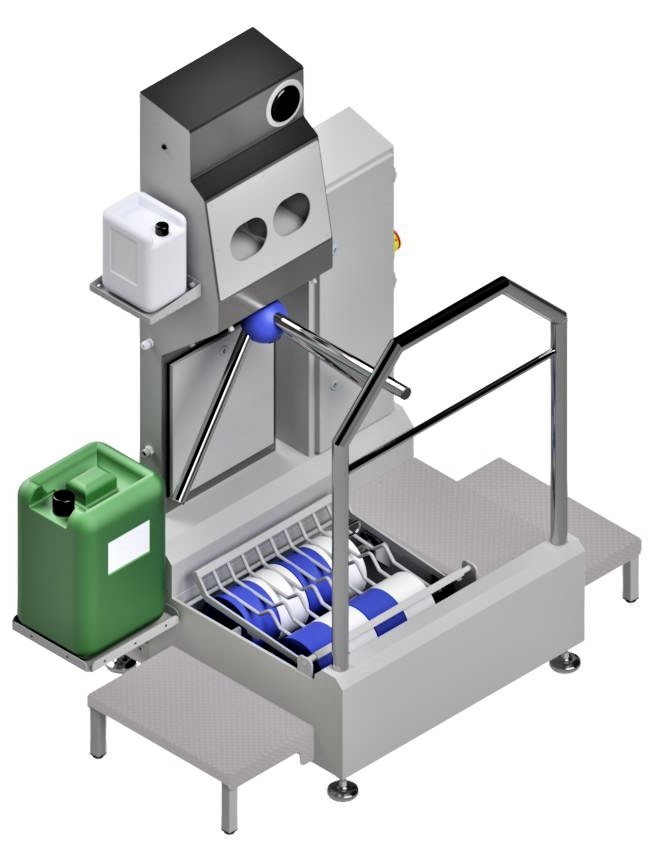

The hygiene sluice forms the perfect basis for a successful hygiene concept and the foundation of an optimal food hygiene concept. The hygiene sluice is manufactured according to your needs, such as the number of employees, your spatial conditions, the actual degree of contamination, and your hygiene requirements. Depending on your requirements, the system includes: sole and shoe cleaning, hand cleaning and hand disinfection, drying, and integrated turnstiles, either automatic or manual.

Product description: Hygiene sluices.

Hygiene Sluice definition: Hygiene sluices are used to prevent the transfer of dirt and bacteria. They prevent contamination in production areas of food businesses, agriculture, bakeries, butchers, hospitals, commercial kitchens, or industrial plants. Hygiene sluices are manufactured in accordance with HACCP standards and are the ideal solution for optimal hygiene conditions.

Planning & implementation of your hygiene lock.

Each hygiene station is individually designed for food businesses, hospitals, commercial kitchens, butchers, bakeries, and many other industries. The facility is adapted to your requirements and can be assembled from the following components: shoe cleaning, disinfection, hand washing, drying, and turnstiles.

Thanks to our many years of experience in manufacturing hygiene stations, we are very familiar with the legal requirements. The most important factor in planning a hygiene lock is the number of employees who need to pass through it. The basic equipment of a hygiene lock includes:

- Hand washing and hand disinfection facilities

- Sole cleaning and sole disinfection facilities

- Shaft cleaning and shaft sole disinfection facilities

- Hand drying system

If there are a large number of employees, it is advisable not to combine the individual work steps such as hand cleaning and hand disinfection as well as sole cleaning and sole disinfection in one device, but to distribute them across different facilities in order to avoid overcrowding at the beginning or end of the shift. This adjustment ensures that the capacity of the hygiene lock is not exceeded.

Top washing results

Sole & shoe cleaning

If you have a large number of employees, it is advisable not to combine individual work steps such as hand cleaning and hand disinfection as well as sole cleaning and sole disinfection in one device, but to distribute them across different facilities in order to avoid overcrowding at the beginning or end of the shift. This adjustment ensures that the capacity of the hygiene lock is not exceeded.

Top results for your hands

Hand cleaning and hand disinfection

Hygienic hand cleaning and disinfection is one of the most frequently used components, regardless of the industry in which the chamber is used. The system ensures that all employees have clean and, optionally, disinfected hands when handling food.

Top drying results

Drying

Hand drying can be optionally integrated into the hygiene lock. Drying can be either automated electrically or by using paper and offers optimal drying results.

Top Turnstiles

Turnstiles

The turnstile in the system ensures that each person follows the sequence required by the company. After successfully passing through the individual stations, the turnstile is released, which can be supported by a visual signal if desired. Our range includes both mechanical and automatic turnstiles and guarantees efficient hygiene compliance.

Information Hygiene sluice

Areas of application

Hygiene locks have a wide range of applications due to their versatility. The following areas of application are conceivable, for example:

- Hygiene locks in the food industry

- Hygiene locks in butcher’s shops, meat processing plants, bakeries, dairies, or similar food businesses

- Hygiene locks for kitchens and commercial kitchens

- Hygiene locks for industry

The system is then customized in consultation with you to improve hygiene in your industrial or food processing facility.

Advantages

Hygiene sluices are an important part of a successful hygiene concept. The hygiene sluices from Heim – EDT GmbH offer the following advantages:

- Hygienic design

- Ensures operational and food hygiene

- Robust design

- High-quality components

- Low maintenance

- Reduces bacterial contamination

- Protects your products from bacterial contamination and improves staff hygiene

We have a wide range of hygiene sluices and would be happy to provide you with a quote at an attractive price.

How hygiene sluices work

Disinfection, hand cleaning, sole cleaning, and shaft cleaning—all aspects of personal hygiene combined in one hygiene sluice. The hygiene sluice for food businesses is individually tailored to your company and your employees. All hygiene sluices and washing systems are HACCP-compliant and feature a hygienic design. Depending on your requirements, your employees can pass through the following stations when crossing:

- Sole cleaning and sole disinfection

- Hand cleaning & hand drying and hand disinfection

- Shaft cleaning

- Electromechanical turnstile

A hygiene station for the food industry can also be equipped with soap dispensers, hand wash basins, towel dispensers, or waste bins for your employees. To improve your employees’ hygiene, these stations can be incorporated into the hygiene stations.

Touchless sensor-controlled soap dispenser or hand sanitizer in the hygiene lock (one-hand operation): dispenses an adjustable amount of liquid hand cleanser for hand cleaning. Touchless sensor-controlled hand washbasin attached to the hygiene sluices, sensor activates the hot water supply for an adjustable time, integrated into the hygiene sluice. Paper towel dispenser for drying hands and improving hygiene, waste bin, (option: warm air dryer).

Touchless sensor-controlled hand sanitizer dispenser for two-handed application, dispenses an adjustable amount of sanitizer onto the hands for improved hygiene. Triggering hand disinfection or hand cleaning causes the turnstile to be released once by means of an impulse; with optical signals for release detection (red cross = locked, green arrow = free).

Turnstile: three-armed, electromechanically controlled. Opposite direction from production can be set to either free or locked. Shoe sole cleaning via pressure activation: when the brush rollers are stepped on, the brush motors and the solenoid valve – cleaning agent and disinfectant supply according to the injector principle – are activated. A hygiene lock is essential when handling food, for example in a butcher’s shop, a kitchen, a commercial kitchen, or other food businesses or the food industry.

We place the highest demands on our hygiene technology, which is why all parts of our hygiene sluices, from hand disinfection and hand cleaning to boot drying, comply with the HACCP concept and are extremely hygienic thanks to innovative design and technologies.

Types of hygiene sluices

- Forced-guided, spatial hygiene sluices: Hygienic components planned within the room

- Forced-guided, compact hygiene sluices: Hygiene components combined in one system

- Hygiene sluice in accordance with operating instructions: Small businesses or side entrances

Depending on the size of your business and the conditions at your location, our health specialists will design a hygiene lock tailored to your needs based on the following criteria:

- Number of people in a given period of time

- Number of shifts

- Degree of contamination

- Compliance with the requirements of the state food control authority

- Individual operational characteristics

Of course, we check whether employees carry work equipment with them and how or by whom the hygiene components need to be cleaned.

When planning, it is essential to take into account the necessary escape and transport routes around the hygiene locks. Our specially designed and field-tested escape route swing doors or magnetic locks comply with the legally prescribed escape width.

In addition to smoke detectors, you can also install a fire alarm system or an emergency release device that ensures quick unlocking of escape routes in an emergency.

Cleaning staff and their equipment, for example, must also be taken into account in the planning.

With regard to subsequent system maintenance, the accessibility of the system must be taken into account during the design phase.

We design solutions that are based on the actual requirements and budget of the customer. Even if the installation of hygiene locks is not always possible in small businesses, we can help you achieve this goal by working closely with your food inspector and architect.

Inquire now:

Contact

Address

in der Spöck 12, 77656 Offenburg

contact persons

- Jörg Walter

- Geschäftsleitung

- j.walter@bw-fpe.com

- +49 (0)781 / 127 864 13

- Kilian Rebmann

- Konstrukteur

- k.rebmann@bw-fpe.com

- Isabella Walter

- Buchhaltung

- info@bw-fpe.com

- +49 (0)781 / 127 864 13